Name. | Magnesia stabilized zirconia powder |

| ||||||||||

Desc. | Light yellow powders | |||||||||||

Tightly sealed with plastic film in PP drum. | ||||||||||||

With advantage of precision,uniform solid solution of magnesia in zirconia crystal phase and Intrinsic performance, product processed with this powders have the characteristics of higher toughness at higher temperature, high temperature thermal stability, low thermal conductivity, good thermal shock resistance and strong resistance to acid and alkali slag. | ||||||||||||

App. | Widely applied in manufacturing oxygen sensor protector and precision structural parts for metallurgical industry; Coating of Turbine blades for energy industry, ballistic missile and protective armor coatings. |

| ||||||||||

Spec. | Grade | ZrO2(HfO2) | MgO | SiO2 | Lg.n | BET | D50 | |||||

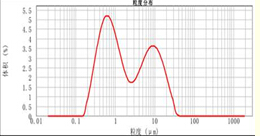

SZ-SC-M | >97wt% | 2.5-3.0 wt% | 0.01wt% | <0.3wt% | 3-5m2/g | 0.8-1.2μm | ||||||

| Suggesting forming method | wet process | |||||||||||

| Typical Flexural strength | >550Mpa | |||||||||||

| Suggesting firing temperature | 1570℃ | |||||||||||

| Typical firing density | >5.7g/cm3 | |||||||||||

| Other impurities such as Si, Fe, Na, Al are controlled below 100ppm, binder type can be customized. | ||||||||||||

Photos. |

SEM of Sintered sample |

Typical particel size distribution | ||||||||||

Remark. | Information showed above only for reference, prevail with the agreed quality standards after sale. Carefully read the MSDS document before using; Process performance may not be suitable for some specific circumstances, please contact our company professional guidance; Product can be customized according to customer specific requirements. | |||||||||||

MgO-Stabilized zirconia powder

Prev:3YSZ powder for CIM

Next:ZTA powder